..........................................................................................................................................................................................................

new kids on the block

most of us have a favoured bike brand, either one arrived at through inspiration, or by means of more pragmatic circumstances, such as ownership or a test ride. though hardly relevant to this particular discussion, two of the sunday morning peloton have recently acquired brompton folding bikes, a brand of velocipede i too have had on my desire list for more than just a few years. however, unlike either of my fellow pelotonese, i can scarcely justify such a purchase, for in truth, i'd have no foreseeable reason to ever fold the bike in the first place.

however, i was offered a brief pedal on the most recent acquisition, just long enough to bolster that latent desire and to discover that the steering is a bit more alert than was i.

but in similar manner to that of the seemingly never ending supply of cycle clothing, the prospective cycle buyer has considerable choice when it comes to filling that extra space in the bike shed. not only is there a bicycle suitable for every conceivable need or requirement, but colour options and material choices are scarcely in short supply. orange steel, blue aluminium or red carbon are hardly off the shopping list and should component choice be of prime consideration, many are available as frame-only, at which point the whole shopping thing begins all over again, albeit on a smaller scale.

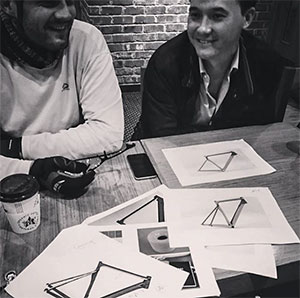

i seriously doubt even a newcomer to the sport would be found bemoaning the lack of choice, so when someone new comes along, from the uk no less, promising that their, 'engineered and built in london', as yet unreleased product, is 'optimised, using state of the art engineering techniques for a more powerful frame', i cannot but deny that the word 'rhetoric' sprang to mind. however, it is hardly fair to judge without further investigation, so i asked the folks at the newly formed tresca bikes about those 'advanced engineering techniques'. how are they any different than the techniques employed by other manufacturers of quality aluminium frames?

"Drawing on our aerospace engineering experience, we evaluated every design decision utilising Finite Element Analysis (FEA) based optimisation to tune the performance of the frame. In the launch product, we've designed every detail from the ground up. In the early stages we defined a number of key ride characteristics such as power transmission stiffness, handling stiffness, ride comfort and weight. We then compared these against our leading competitors to set our targets.

"Tresca are by no means the first brand to bring this engineering expertise to the bike industry, and many of the other major players are also utilising similar expertise and techniques. However we believe that we've identified a market niche currently neglected by existing brands. As riders and engineers, what we see in existing products is an elitism of high quality engineering being reserved for exotic high cost products. In bikes priced between £1000 and £2000 we see the looks and marketing of elite models, but too often with minimal engineering and optimisation of the materials used at this price point."

it's fairly clear from the above answer that a tresca bike is not one liable to fall to pieces before the warranty runs out. the folks in london certainly seem to have their sh*t together (so to speak). but perhaps the most unusual aspect pertaining to tresca is use of the phrase 'engineered and built in london' to introduce prospective buyers to their website. though the resurgence of steel as a viable frame material, only a matter of a decade or so ago, has brought to light many individual framebuilders, even stretching as far as mass-production models, we have become inured to the supposition that most of what rides today's sportives has been built and/or assembled in the far east. is tresca building its aluminium frames in the uk, or are they too constructed in the far east?

"Our bicycles use a high-end, hydroformed 6069 aluminium frame designed and engineered in the UK, but manufactured in Taiwan. The manufacturing is done using our own hydroforming moulds, while the frames are subsequently joined together in our own welding jigs. The frames and components will be delivered to the UK separately, arriving from our global chain of suppliers and built into complete bikes in our UK assembly plant."

the chaps at tresca are not naive enough, however, to believe they're the only ones treading this individual path. though their construction techniques may well provide us with state of the art alloy frames, unless we can purchase them for a few pounds less than the established competition, there's a better than evens chance that tresca might remain significantly low on the wishlist. economics, however, can play every bit as large a part in the quest for the dithering customer as does shiny tubing. tresca claim to have achieved this very state by means of a vertically integrated, lean business model. as one with no training in economics whatsoever, nor even a particularly decent grasp of numbers, what does that mean?

"In essence, it means removing any extra middlemen and costs between the factory and the consumer. By selling it directly through our ecommerce site, we can cut out everyone and everything that doesn't add value, such as the wholesaler, regional distributor, store overheads etc.

"We intend to operate differently to our competition by concentrating on supply-chain efficiency to setup more lean distribution strategies, reducing overheads and improving operational efficiencies ultimately producing just what's actually needed. This will allow us us to be more flexible and quicker to react to market trends, ultimately enabling us to offer bicycles at competitive prices."

talking round the houses is something in which i perhaps indulge too often; more readily defined as 'beating about the bush'. it's also none too surprising that marketing mostly does likewise, careful to bring to light all salient features without bringing the bottom line into disrepute. however, midst all the engineering and production banter, what we'd really like to know is what sort of money tresca would like to relieve us of in the process of our becoming avant garde?

"We're aiming to market our first full bike for no more than £1500 featuring our optimised aluminium frame with a carbon fork. This will feature a Shimano 105 groupset, DT Swiss R24 Spline wheels, and Fizik finishing kit. Pricing is, of course, subject to final pricing from our component suppliers. We also hope to offer the frameset and carbon fork for around £800."

it's hard to deny that those numbers are less than stratospheric and within the reach of many of today's pelotonese and those keen to join. but tresca aren't entirely alone in the often cut-throat world of bicycle sales, where frequently low-priced machinery is built down to a price point rather than up to a specification. if we accept this as an immoveable truism, who do tresca see as their main competitors?

"Due to our ambitious nature, we see our main competition coming from similarly priced models from the major players. However, what we find very encouraging is a revival of aluminium framesets from the big brands too. To pin it down to individual models, we can't fail to target the highly acclaimed Cannondale CAAD12, the lightweight Trek Emonda ALR and the stylish BMC roadmachine RM03.

"In our development cycle, we've focused on creating a bicycle which combines the best aspects of the competition into one single, superior product."

in the process of highlighting the bicycles that they see as their direct competition, tresca have almost inadvertently pointed out a variety of choice that we may already have found to be very much to our advantage. trek, cannondale and bmc have all been around for quite a while and all have achieved successes in the competitive realm that plays to our weakspots when it comes to heading to the bike shop. we're hardly short of choice, so do the chaps at tresca figure that there's actually room for yet another bicycle manufacturer in a crowded market?

"Bike consumers are smart. They research products and technology before they make purchases and they love their sport. We are aiming to make better bikes than our competitors and if we achieve this, then there is definitely room in the market for Tresca.

"By removing any middlemen, we'll be able to serve our customers a lot better than many big brands whose products are sold in stores. Communicating directly with the customer means we're able to address their questions, providing feedback to our designers and adapting to market trends a lot faster than the big brands who simply cannot do so with their existing distribution networks.

"We also believe that there is room for a British road bike brand. As a nation we have a great reputation for winning the sport's biggest stages, but currently there's currently no high-end, direct to market, British road bike brand. We see this as a major opportunity."

there's little doubt that tresca offer a compelling case. the notion of a high-quality, british road bike is one that's probably highly attractive to many a uk cyclist, one that strives to join the ranks of top cycle-clothing purveyors such as rapha, le col and endura who currently fly the flag proudly across the world. but that leaves me with just one question: why should i buy one?

"Because we will have made you a great bike, offering great performance, improved power and more comfort than our competitors, all proven by scientific engineering optimisation, accompanied by great looks and at a great price.

"It will also be super cool to say you were one of the first to own a Tresca bike!

"With this, our first product, we are aiming to launch a brand with ambitious plans for the future. The Tresca Engineering team have vast composite engineering expertise and we are excited to start applying it to the bicycle industry. But we will only do so when we feel using carbon composites will bring a better end product to the rider. Will it be on a high end time trial machine or a super compliant gravel bike? Only time will tell.

We aim to enter the market with our production road bikes within a couple of months."

you can follow tresca's development process at tresca bikes

friday 30 march 2018

..........................................................................................................................................................................................................

..........................................................................................................................................................................................................