..........................................................................................................................................................................................................

mavic k10 wheel/tyre system

it's no secret that those of the carbon persuasion who are now offering us carbon rims for our clincher tyres, had many a happy day scratching their heads in the research and development department, trying to figure out how to stop the tyres blowing the rims to pieces when up to pressure. aluminium rims cope with these sort of pressures really well, or at least a lot better than carbon, the latter being particularly brittle unless suitably reinforced in the appropriate vector plane. the recently tested carbonsports lightweight clinchers featured a large warning sticker on the rim against inflating beyond 8 bar for that very reason.

we pretty much take it for granted that popping any clincher on any aluminium rim is technical simplicity itself, always assuming that the tyre slips on easily in the first place. i know i'm not the only one who has come across a more than recalcitrant example which refuses point blank to go those extra few centimetres and slide over the rim bead, leaving a trail of broken tyre levers and very sore thumbs in its wake. however, this incompatibility (almost) with carbon should perhaps have alerted us all to the fact that sweetness and light were mere fractions away from all out war twixt hoop and tyre (i exaggerate, but only for the sake of excitement).

mavic, they of the yellow following cars, have been making wheel rims since 1934, and it would ill behove any of us to doubt their veracity for creating some of the finest bicycle rims on the market today, and it is not likely that they got to where they are today without knowing a thing or two about how an inflated tyre and tube affects their products. whether the various tyre manufacturers study the same from the opposite side of the fence i know not. it was, perhaps, only a matter of time before mavic decided that the knowledge gained over those years would persuade them that they maybe knew enough to match a pair of tyres with rims; which, of course, is exactly what they have done with the recently released k10 system.

the 23c tyres are almost featureless, in that they are solid black with no tread whatsoever, superficially similar, in fact, to a pair of schwalbe ultremos, but with a bit more texture to the tread. mavic denote this as griplink, a dual compound surface meaning a bit more elasticity and grip on the shoulder, and harder wearing in the centre. the only markings that identify either front or rear as being from mavic, are the red. white and yellow k10 logos on the sidewalls. if i understand the literature correctly, the tyres are apparently known as mavic yksion, but this is only referred to on the wheel rim and strangely not on the tyres.

the wheels are a development of mavic's incredibly successful ksyrium series, with the weight reduced to a mere 1470 grams principally by machining excess metal from the side of the rim in panels just below the braking surface. the flat spoke count is predictably minimal at a mere 18 on the front wheel and 20 at the back, but strangely the rear is radially laced on the drive side and two cross on the non-drive, contrary to the notion that the former experiences greater stresses than the latter. the rear hub reassuringly features a very thick and heavily machined non-drive flange. the zicral flat bladed spokes are tensioned in the rim by splined spoke nipples which require a proprietary spoke wrench (supplied) should the wheel need truing. the wheels also arrive with the necessary tools to adjust the cones when a modest degree of play eventually arises.

at least some of the weight loss must also have been achieved by exchanging the former ksyrium front alloy hub for a carbon fibre model, thus the front wheel tips the scales at a rather scant 638 grams, and the whole kit and caboodle, rims, tyres, tubes weighs only 2100 grams. it's interesting to compare weights such as these with today's state of the art carbon frames at under 1kg.

the wheels arrived in two cardboard boxes complete with mavic logo'd wheelbags, skewers and the necessary bits and bobs to maintain them in the manner to which they are likely wont to become accustomed. helpfully, the tyres and tubes are already fitted at point of receipt, and it's a nice touch that the logos on the tyres are matched to the logos on the wheels. the rear supplied featured mavic's m10 freehub, splined to accept either shimano or sram cassettes. since these are currently fitted to a colnago master running campagnolo centaur, i fitted an american classic compatible cassette. additionally, for the time being i have eschewed the mavic supplied skewers, replacing them with a rather fabulous and minimal pair of corrosion free titanium skewers from van nicholas. (more about these in the coming days).

i have perhaps made my point clear regarding the spoke count and lacing of so-called boutique wheels, in that i generally regard them with suspicion. are the spokes straight and radial because it makes it easier for machines to build them, or is there really a reputed advantage in so doing, and i am merely cynically inclined? in the case of mavic's k10 pairing, i fear it may be the latter, for these ride easily as well as many a handbuilt pair encountered over the years. there is no doubting their stiffness and aptitude for the job of riding very quickly;

or at least as quickly as i can manage, but it is a mystery as to how comfortable they are when given a bit of a doing over a sequence of cattle grids and roads with a surface comparable to that of the sea of tranquility. i employed, yet again, my totally unscientific procedure of closing the rear brakes as much as i dare, popping the bicycle into the outer ring and pushing as hard as my little legs would carry me. the unscientific bit is the fact that this has almost as much to do with the frame's rear triangle as it is with the wheel itself, but in any case, i was unable to encourage any rubbing on the rear rim, thus mavic's drive side radial lacing must be the biz after all.

or at least as quickly as i can manage, but it is a mystery as to how comfortable they are when given a bit of a doing over a sequence of cattle grids and roads with a surface comparable to that of the sea of tranquility. i employed, yet again, my totally unscientific procedure of closing the rear brakes as much as i dare, popping the bicycle into the outer ring and pushing as hard as my little legs would carry me. the unscientific bit is the fact that this has almost as much to do with the frame's rear triangle as it is with the wheel itself, but in any case, i was unable to encourage any rubbing on the rear rim, thus mavic's drive side radial lacing must be the biz after all.

the tyres are great. on a bicycle that positively encourages squiggly stuff on corners, descents and a combination of the two, the grip was marvellous, even on the sketchy, gravely stuff that inhabits the bits of road that you'd really rather it didn't. strangely, and rather contradictorily, when standing up to climb the occasional rough stuff on the hills, the back wheel provided a little hop, skip and a jump, suggesting that grip was being lost. however, these are not the only tyres that do this on our roads, so i'm not sure it's anything to be seriously concerned about; on smoother surfaces, grip was as exemplary as you'd expect. my theory, should you be interested, is that the lightness of the wheel is a contributory factor, but on a 75km ride it really only happened on a couple of occasions and the road surface didn't look like a billiard table.

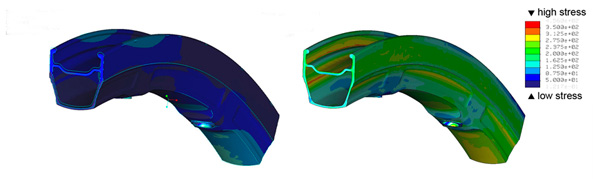

despite my having a higher in physics, i don't remember anything concerning pressures exerted on metallic structures, so despite mavic's pretty pictures on the website, i have to put my hand up and plead ignorance of such matters; the only tangible evidence available is the riding i've been doing for the last few weeks. on that basis, mavic are pretty much on the money with this pairing, a combination that has already been developed further with the recently announced 2011 range available early next year. meantime, if you're in the market for a pair of wheels that seem to do everything particularly well, on a wide variety of road surfaces, the k10 system should be at or near the top. recommended retail is around the £900 mark, but i have seen them offered recently for as little as £600.

it's rather comforting to know that not only are mavic continuing their seemingly endless devlopment, but that they have our very best interests at heart.

posted saturday 11 september 2010

..........................................................................................................................................................................................................